Higher capacity, compliance, and easier maintenance were the driving forces

As the county seat of Osceola County in central Florida, just south of Orlando, Kissimmee is best known for its proximity to the many amusement and theme parks in the area, including Universal and the Walt Disney World Resort. Kissimmee, situated on the north shore of Lake Tohopekaliga, obtains water and wastewater services from the Sandhill Water Reclamation Facility (WRF) of Toho Water Authority. As the largest provider in Osceola County, Toho water serves upwards of 160,000 customers in the greater Kissimmee metropolitan area.

Originally built as a 6 MGD (million gallons per day) facility, the Sandhill WRF needed to be upgraded and expanded. There were compliance issues, but the substantial population growth over the past couple of decades and the anticipated continued growth in the coming years also needed to be addressed. Town officials, working with Carollo Engineering and alongside Wharton-Smith as the construction manager, determined that a 50% expansion was necessary – with an increase needed from 6 MGD to 9 MGD. Upgrading the old flat panel aeration system to meet the new capacity, the treatment impact for the plant was targeted at 1.62 million KG/year of BOD removal and NH₃ removal of 321,000 KG/year.

Nutrient Pollution

Water treatment facilities around the globe, like Sandhill, play an important role in minimizing nutrient pollution in our waterways. Naturally occurring nutrients (primarily nitrogen and phosphorus) at normal, balanced levels in streams, rivers and other bodies of water are healthy, as they support the growth of algae and aquatic plants. These plants in turn provide food and habitat for fish, shellfish, and smaller organisms that live in water. Too much nitrogen and phosphorus, however, creates what is referred to as nutrient pollution. Nutrient pollution can deteriorate water quality as algae can grow rapidly, reducing or even eliminating the oxygen supply and reducing the exposure to sunlight. This leads to habitat damage, loss of aquatic life, drinking water contaminated with toxins and bacteria, and ultimately negative impacts on human health.

Doing Their Part

In an ongoing effort to minimize excessive nutrients in their effluent, the Sandhill WRF is designed to have four total basins, with seven different aerated zones with different diffuser densities. Each basin uses a four-stage Bardenpho process that required multiple tank zones operating with settings of AOAO – Anoxic, Aerobic/Oxygenated, Second Anoxic, and Small Reaeration/Oxygenation steps for nitrogen removal. Additional zones within the tanks were also designated as swing zones, to be used only when needed. Given the complexities of the existing operation, and the different diffuser densities depending on the basin, the seemingly simple upgrade to accomplish the new parameters of the WRF was actually going to be quite a challenge.

Not So Simple

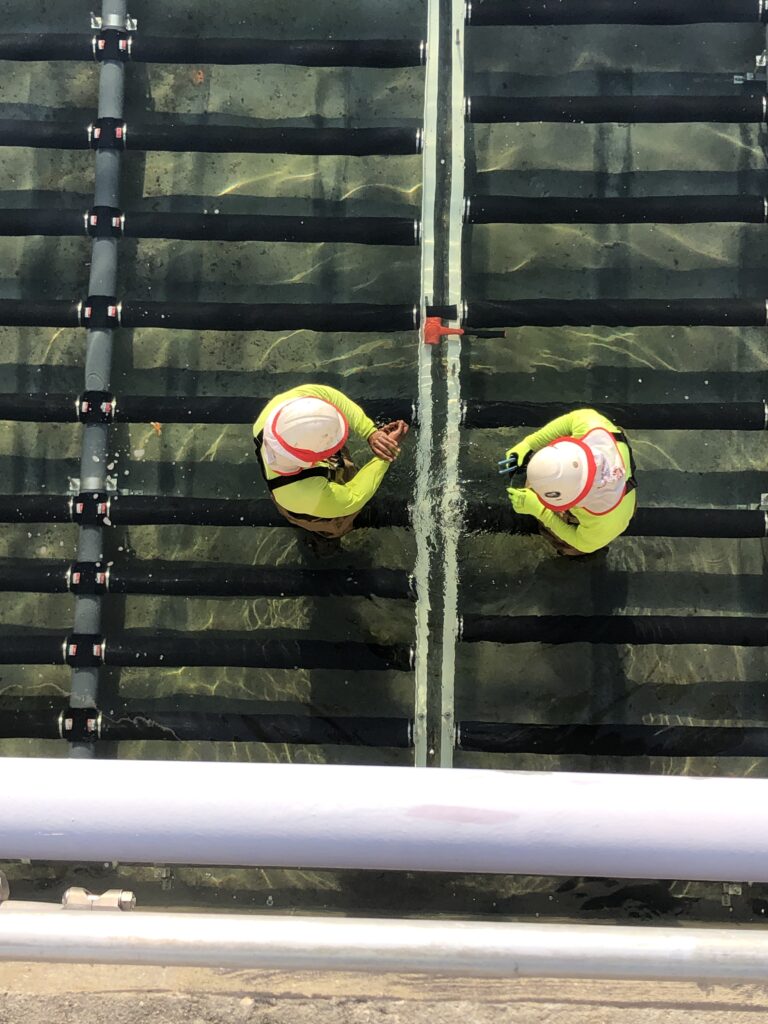

The Carollo Engineering team set out to determine the ideal solution for the facility, and pulled together a design that incorporated EDI FlexAir® Pro MiniPanel™ diffusers (MP3 model) as the primary technology to address the needs of the plant.

EDI FlexAir® Pro MiniPanel™ diffusers – model MP3.

The high-efficiency and high-density diffusers, supplied with EPDM (ethylene propylene diene monomer) micropore membranes, were chosen due to their easier maintenance, chemical resistance, and added UV protection – ideal for municipal applications like Sandhill. Since some of the zones had mixers, creating high water velocity in the mixer zones, EDI also supplied diffuser end-supports and pipe support side-bracing, so the system could withstand the higher turbulence. In-basin piping was made of Schedule 80 PVC and mounted with Type 316 stainless steel, for added corrosion-resistance and durability. In total, 1,068 units of MP3 diffuser arms were supplied for the basin upgrade.

Timing is Everything

In order to keep the water reclamation facility online during the renovation process, Wharton-Smith worked with the Sandhill team to schedule the work in stages, essentially taking one tank offline at a time. The first basin was completed in May 2022, with basin 3 completed in July 2023 and basin 2 reaching completion in August 2023. Basin 4 was not part of the upgrade project, so there weren’t significant changes made at this time. In addition, some diffuser locations had to be removed due to pillars in the tank, but it was determined that the system had enough aeration capacity to make up for this reduction.

Ever since the project was completed in August 2023, all systems are running smoothly and the plant is in compliance.

“We are really pleased with the efforts of the EDI team, pulling together a solution for our expansion,” says Shane Howard, Chief Operator at Sandhill WRF. “We were able to maintain operations during the entire process, which was critical. And with the upgrades now complete, we are meeting our discharge requirements and minimizing the amount of nutrients in our effluent. They did a terrific job.”

It is optimized facilities like Sandhill WRF, that minimize nutrients in their effluent, who help to address nutrient pollution in our communities by reducing nitrogen and phosphorus in our waterways and water supply.